5/14/16 Saturday - My wife and daughter drove down to Richmond to look at a college, and I stayed home to fix a leak I discovered when fixing the dishwasher last week, except the part hadn't arrived yet. So I had a whole day (five hours or so) to work on the band saw.

I found some more scraps of that maple bed frame I was using before. It's the PERFECT thickness for this next batch of parts. 3.2 cm thick.

First up is the frame that holds the shaft mount for the top wheel.

Each side of the frame is a different width and length, and the top and bottom need lips cut into them or holes drilled in them

My table saw's scale seems less exact at narrow widths, and it shifts slightly when I lock the fence down, so I use a caliper to measure things. Here, I'm setting up to cut notches in the ends of the side pieces. I think. Stop block on the miter gauge. One of these days I'll make a sled.

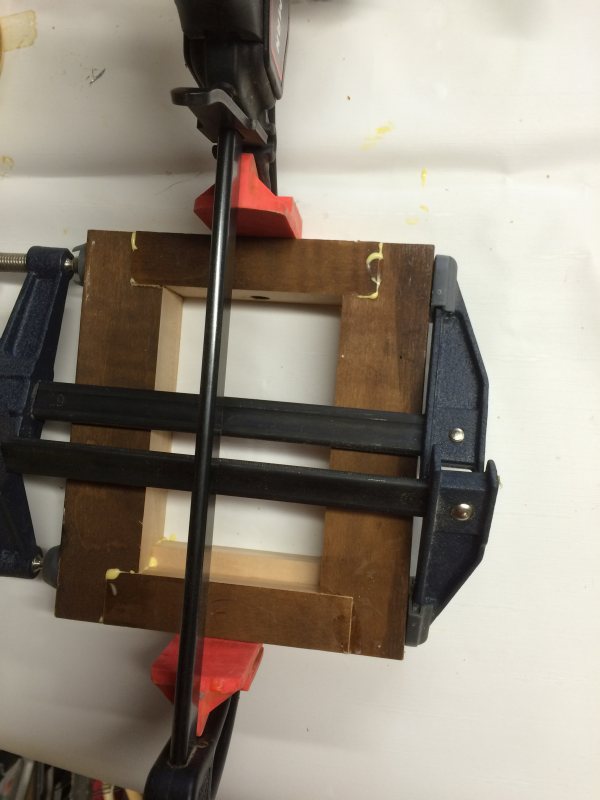

And this is the frame being glued up. After this dries, I'll cut 4 slots for splines in each corner. This needs to be a strong joint and it's way too weak glued up like this.