Sunday 5/22 continued

I had made the frame for the top mounting block last time I was working on the band saw, and I need to reinforce the corners. It will be holding the tension of the blade, so the corner joints of this box need to hold a couple hundred pounds of force each. So I need to take those weak butt joints and reinforce them with splines. Kind of like making my own plywood.

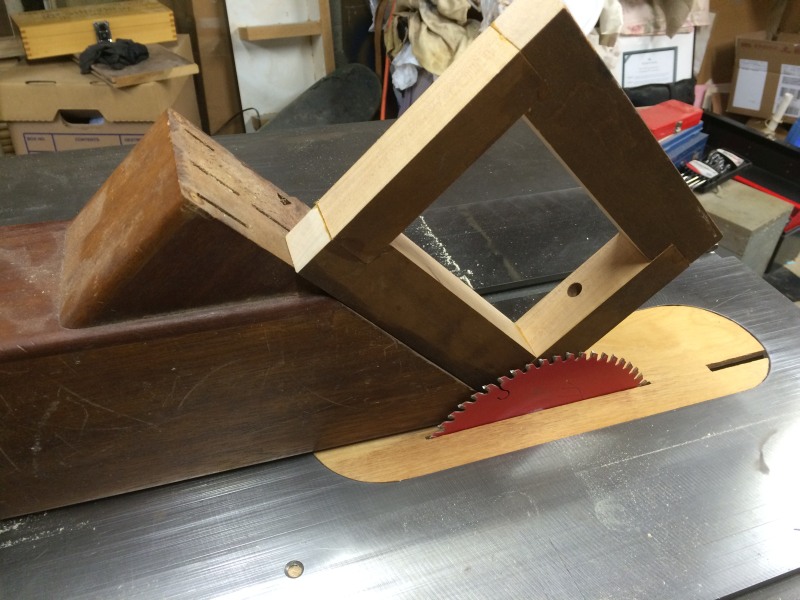

I started by figuring out how to hold the frame at a 45 degree angle to the table top. I had picked up this knife storage block off the curb in front of my neighbors’ house on trash day years ago. They were moving out and put a ton of stuff on the curb. I never knew what I would use it for, but it seemed like it would come in handy some day. Today is that day. It’s my jig for holding the frame at 45 degrees. Here, I’m holding it next to the saw blade to set the blade height.

Next I put the fence in the right spot and visualized how the cut would go. I wasn’t happy with it. The fence was too short and the work piece wanted to rotate over the fence when I pressed it to the fence. It would ruin the cut and might cause a dangerous situation.

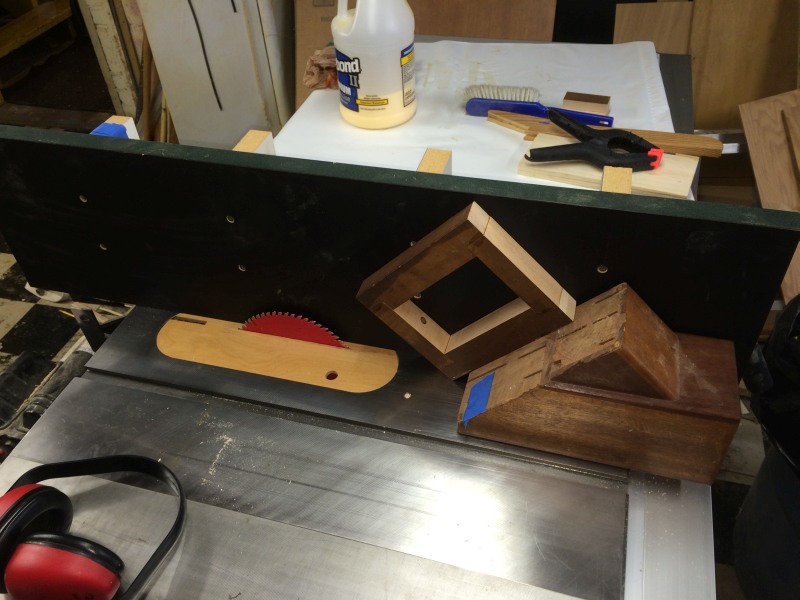

So I dug out an auxiliary tall fence I had made for a router table that I never use. This tall fence was made from a counter top I dug out of the trash at work. The counter was perfectly good, but they were redoing the space and tossed it. Nice melamine over very thick particleboard. I also put some blue tape on the knife block jig to tell me how high the blade was. This felt much more secure and sturdy. I’m happy with it.

So I made a bunch of cuts. 20 to be exact.