8/21 Sunday. Another couple hours

I let an hour or so get away from me without taking any pictures.

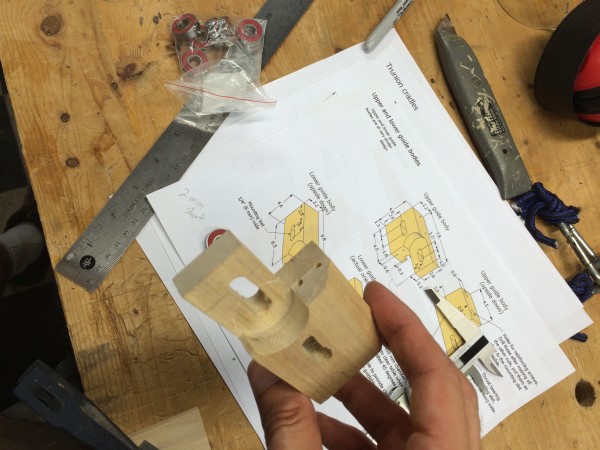

To get to this point in making the lower blade guide assembly support block, I started by cutting a block to size. Drilled the two slots on the drill press.

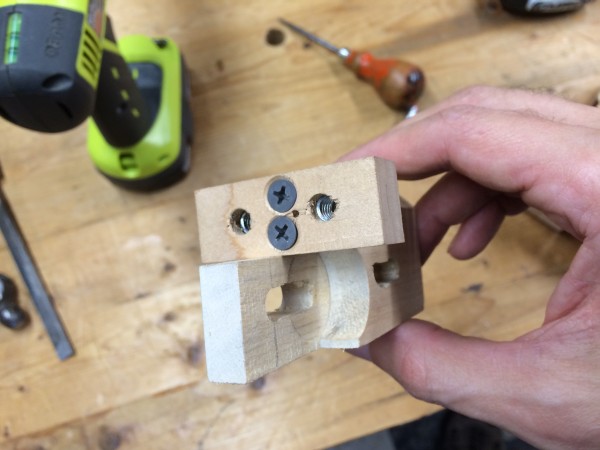

Cut the corner miter off on the table saw by tilting the blade and doing a rip cut. (edit: actually, now that I think about it, I used a hand plane, an old bedrock #605, to plane that bevel on that corner.) Drilled the large hole that accepts the ball bearing using a forstner bit in the drill press. Then I cut away the two notches at the end of the piece on the table saw so that that tongue would be sticking out. In this picture I have it clamped in a vise to get two pilot holes drilled at those points on the right.

One of the slots is ugly because the drill bit wandered a little in the grain. But I tested it out and a bolt still slides back and forth in that slot without too much trouble.

I tested the fit of the screws by attaching the support block for the side blade guides.